New spin Seebeck thermoelectric device with higher conversion efficiency created

A thermoelectric (TE) device using cutting edge thermoelectric conversion technology has been created by a team comprising NEC Corporation, NEC TOKIN Corporation and Tohoku University.

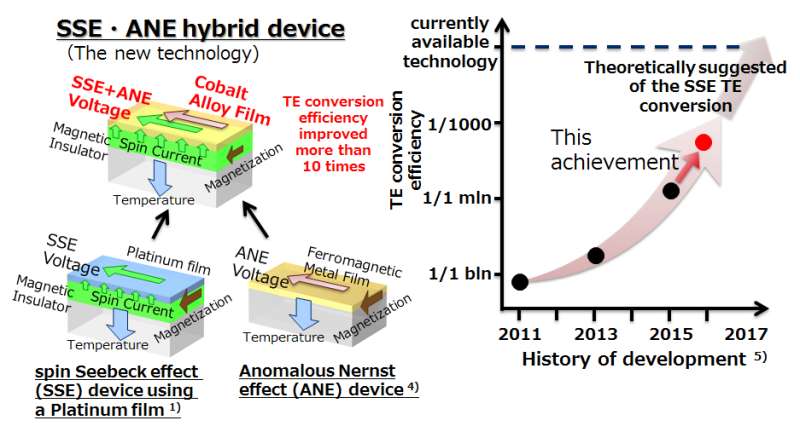

The new technology, known as the spin Seebeck effect, has conversion efficiency 10 times higher than the conventional method.

Thermoelectric conversion technology that converts energy abandoned as waste heat back to electric power could potentially save energy and reduce greenhouse gas emissions. Although conventional spin Seebeck thermoelectric devices have the advantage of low manufacturing costs and high versatility and durability, their energy conversion efficiency is inferior.

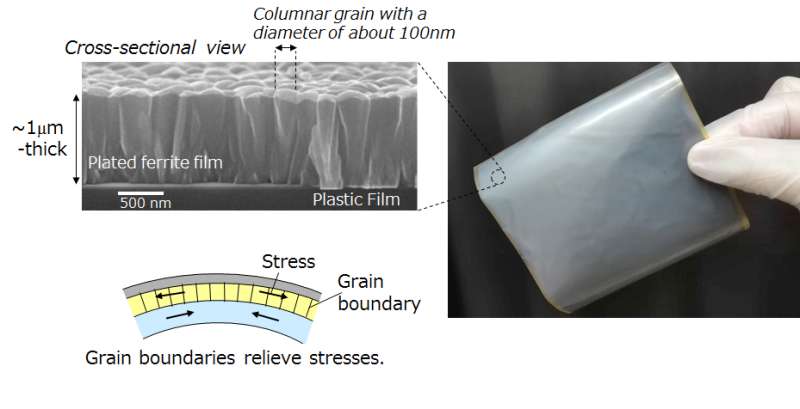

"We have improved the conversion efficiency of this spin Seebeck thermoelectric device by more than 10 times because of its newly developed material and device structure," says Soichi Tsumura, General Manager, IoT Device Research Laboratories, NEC Corporation. "Furthermore, devices made of flexible material, such as resin, have been achieved using a manufacturing process that does not require high-temperature heat treatment."

"The conversion efficiency of this new spin thermoelectric device has been improved by almost one million times when compared to the earliest device, and has taken an important step towards practical use as a generator element. The achievement of practical use as a heat flux sensor is also in sight," says Tsumura.

The three parties aim to further the research and development of technologies to generate electricity from the large amount of waste heat emitted by things such as plants, data centers and vehicles.

These results were achieved as part of the "Saitoh Spin Quantum Rectification Project" led by Tohoku University Professor Eiji Saitoh. It is funded by the Exploratory Research for Advanced Technology (ERATO) program of the Japan Science and Technology Agency (JST).

More information: Akihiro Kirihara et al. Flexible heat-flow sensing sheets based on the longitudinal spin Seebeck effect using one-dimensional spin-current conducting films, Scientific Reports (2016). DOI: 10.1038/srep23114

Journal information: Scientific Reports

Provided by Tohoku University